제품소개

Heating and Cooling

Water-Cooled ChillerHeating and Cooling

Feature

- High Efficient Design

- Special efficient heat transfer inner threaded copper pipe increase heat transfer efficiency and energy efficiency.

- Application of the principle of cold and hot exchange is suitable for the modern industrial's cooling field.

- It adopts the latest machine technology and single-stage vapor compression circuit which is durable, high speed cooling ability and stable temperature controlling.

- It uses the U type heat exchanger which is easy to take out for cleaning and repair.

- Optimized Protection Function

Compressor over load portection, pump over load protection, reverse-phase and phase shortage warning, protection against freezing and high and low pressure protection device.- Cooling temperature range 7~35℃.

- Stainless steel temperature-holder box.

- Anti-freezing protection device.

- Utilizes R22 refrigerant, which can be instead of environmentally friendly R407C refrigerant.

- Refrigeration circuit adopt high and low pressure switch control.

- Compressor and pump are equipped with overload protection device.

- Adopting self-optimizing temperature control circuit boards, precision of ±1℃.

- Wide Range of Application

- Used in plastic processing machinery mold cooling, it can greatly improve the surface finish of plastic products and reduce the surface pattern marks and internal stress so that the products do not shrink.

- Used in CNC machine tools, coordinate boring machines, grinding machines, machining centers, machine tools, various combination of precision machine tool spindle lubrication and hydraulic system, transmission media.

- Used in pharmaceutical, chemical, food and other special industires.

- Variety Option

Low-pressure pump is standard accessory. It can be replaced by the medium pressure or high pressure pump as customers' need. Water tank level gauge is optional.

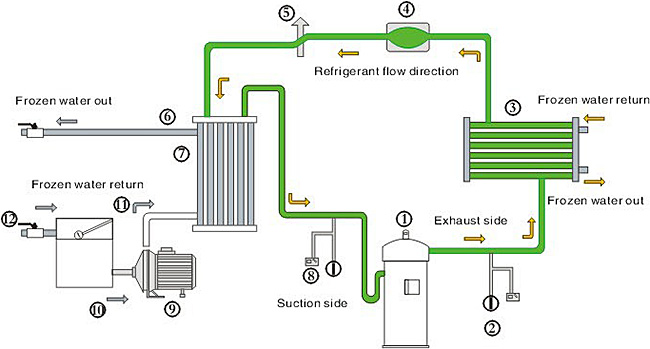

Working Schematic

- Compressor

- High pressure controller

- Condenser

- Dry filter

- Expansion valve

- Antifreeze switch

- Evaporator

- Low pressure controller

- Water pump

- Tank

- Float switch

- Globe valve

Specification

| Model | EC-1.5W | EC-3W | EC-5W | EC-8W | EC-9W | EC-12W | ||

|---|---|---|---|---|---|---|---|---|

| Rated cooling capacity | 50Hz | Btu/h | 17411 | 33457 | 42334 | 77498 | 82960 | 110614 |

| Kw | 5.1 | 9.8 | 12.4 | 22.7 | 24.3 | 32.4 | ||

| Kcal/h | 4385 | 8426 | 10662 | 19518 | 20894 | 27859 | ||

| USRT | 1.5 | 2.8 | 3.5 | 6.5 | 6.9 | 9.2 | ||

| Power | ~200-220V/1Phase/50Hz | ~380-415V/3Phase/50Hz | ||||||

| Compressor Power | Kw | 1.34 | 2.54 | 2.96 | 5.49 | 6.35 | 8.82 | |

| Throttling Device | Capillary tube | Thermostatic expansion valve | ||||||

| Refrigerant | R22 | |||||||

| Condenser | Type | Tube-fin-style (plate) | Tube-in-shell (shell and tube) | |||||

| Water Flow | ㎥/h | 1.11 | 2.13 | 2.65 | 4.86 | 5.28 | 7.10 | |

| Pipe Dia. | DN | 25 | 32 | 32 | 40 | 40 | 50 | |

| 50 | Form | Dry type water tank/ Dry type tube-in-shell style | ||||||

| Tank Capacity | L | 55 | 55 | 55 | 145 | 210 | 210 | |

| Cooling Flow | ㎥/h | 0.88 | 1.69 | 2.14 | 3.91 | 4.19 | 5.58 | |

| Pipe Dia. | DN | 20 | 25 | 32 | 32 | 40 | 40 | |

| Internal Pump | HP | 0.5 | 0.5 | 0.5 | 1 | 1 | 1 | |

| Weight | kg | 100 | 120 | 130 | 315 | 330 | 355 | |

| Model | EC-16W | EC-20W | EC-25W | EC-30W | EC-40W | EC-50W | ||

|---|---|---|---|---|---|---|---|---|

| Rated cooling capacity | 50Hz | Btu/h | 148168 | 221227 | 267316 | 296335 | 442454 | 534632 |

| Kw | 43.4 | 64.8 | 78.3 | 86.8 | 129.6 | 156.6 | ||

| Kcal/h | 37317 | 55718 | 67326 | 74635 | 111436 | 134652 | ||

| USRT | 12.3 | 18.4 | 22.3 | 24.7 | 36.8 | 44.5 | ||

| Power | ~380-415V/3Phase/50Hz | |||||||

| Compressor Power | Kw | 10.84 | 17.64 | 18.97 | 21.68 | 32.52 | 39.3 | |

| Throttling Device | Thermostatic expansion valve | |||||||

| Refrigerant | R22 | |||||||

| Condenser | Type | Tube-in-shell (shell and tube) | Tube-fin | |||||

| Water Flow | ㎥/h | 9.34 | 14.20 | 16.75 | 18.69 | 27.92 | 33.74 | |

| Pipe Dia. | DN | 50 | 65 | 65 | 65 | 80 | 80 | |

| 50 | Form | Dry type water tank/ Dry type tube-in-shell style | ||||||

| Tank Capacity | L | 360 | 510 | 510 | 510 | 600 | 780 | |

| Cooling Flow | ㎥/h | 7.48 | 11.16 | 13.49 | 14.95 | 22.32 | 26.97 | |

| Pipe Dia. | DN | 50 | 50 | 50 | 65 | 80 | 80 | |

| Internal Pump | HP | 2 | 2 | 2 | 3 | 5 | 5 | |

| Weight | kg | 650 | 750 | 1050 | 1360 | 1390 | 1420 | |

※ We reserve the right of change the specifications without prior notice.

Dimension

| Model | W×D×H (mm) | Model | W×D×H (mm) |

|---|---|---|---|

| EC-1.5W | 465×790×860 | EC-16W | 710×1600×1770 |

| EC-3W | 465×790×860 | EC-20W | 710×1600×1730 |

| EC-5W | 480×790×975 | EC-25W | 820×1880×1830 |

| EC-8W | 660×990×1320 | EC-30W | 820×1880×1830 |

| EC-9W | 660×990×1320 | EC-40W | 1050×1880×1830 |

| EC-12W | 660×1220×1370 | EC-50W | 1050×1880×1830 |