제품소개

Heating and Cooling

Mould Sweat DehumidifiersHeating and Cooling

Feature

- Wide Application

- Stable optimized production conditions is crucial to improve product quality and production efficiency, EM mould sweat dehumidifiers remove the moisture on the mould surface which increases the products quality and production, can make drying degree of mold meet the production requirements.

- It is used to deal with the moisture on the mould which orms from the use of dhilled water for reducing the moulding cycle time, particularly while moulding of the PET performs.

- The water vapor comes into being when the temperature of moulding surface is lower than dew point temperature of surrounding air.

- The machines use honeycomb rotors to carry out dehumidifying function, which generates a dry airflow with dew point below -5℃ and ensures the surrounding air of mould remaining in a low dew point temperature. It provides constant low dew point surrounding air to the mould surface all year round without being influenced by the change of seasons.

- Moisture condensation causes corrosion of mould and affects the quality and production efficiency of the products.

- Adopting advanced new-type honeycomb rotor and environmental protection and energy saving design overcomes the shortages of traditional honeycomb forming difficultly, wearing easily, deterioration fast.

- Air outlet uses optimized cooling device to ensure the low temperature of drying outlet wind.

- Reliable Working Characteristic

- New honeycomb wheel and environmental design, Dehumidification and drying performance is extremely stable.

- The quality of products is not affected by the condensation on the mold surface.

- Extending the life of mould and reducing product defect ratio.

- Do not need to change the production environment.

- Accurate control and display of regenerative temperature by using P.I.D Controller.

- Real-time display of regeneration temperature setting and the actual operating temperature.

- Return air cooling and filtering are included.

- Phase reverse and motor overload alarm functions are included.

Optional Devices

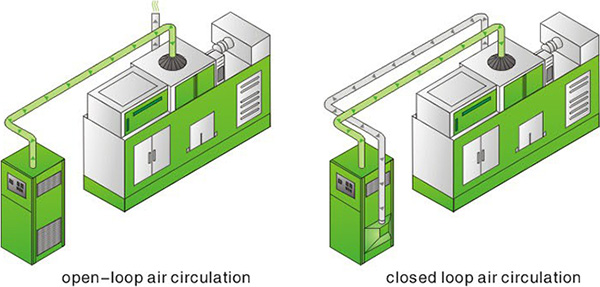

- Return air collector, closed-loop, particularly suited to the warm and humid areas.

- Open-loop air circulation and closed loop air circualtion for choose.

Specification

| Type EM- | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | ||

|---|---|---|---|---|---|---|---|---|

| Drying Blower | kw | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | |

| Regeneration Blower | kw | 0.4 | 0.75 | 1.5 | 2.2 | 2.2 | 3.0 | |

| Regeneration Heater | kw | 4 | 7.2 | 12 | 21 | 21 | 28 | |

| Air Flow | ㎥/hr | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | |

| Pipe Dia. | inch | 4 | 5 | 6 | 8 | 8 | 10 | |

| Air Outlet Temperature | ℃ | 10~20 | ||||||

| Cooling Water Flow | ℓ/min | 40 | 80 | 120 | 160 | 200 | 300 | |

| Cooling Water Pressure | kgf/㎠ | 2~5 | ||||||

| Dimension | W | mm | 650 | 800 | 1150 | 1300 | 1300 | 1400 |

| D | 750 | 850 | 1100 | 1100 | 1100 | 1250 | ||

| H | 1700 | 1700 | 2000 | 2000 | 2200 | 2200 | ||

| Weight | kg | 270 | 350 | 360 | 460 | 500 | 560 | |

※ We reserve the right of change the specifications without prior notice.